Steel Plant Performance

Steel processes

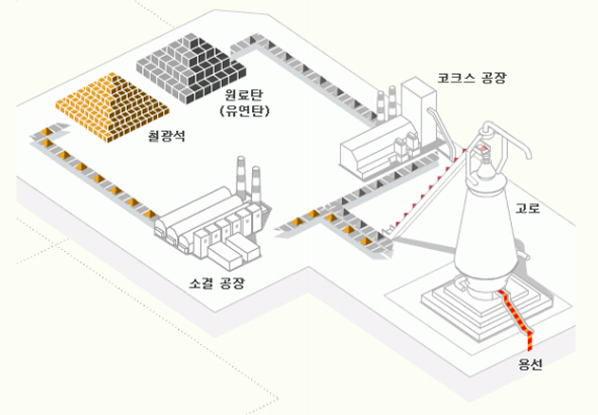

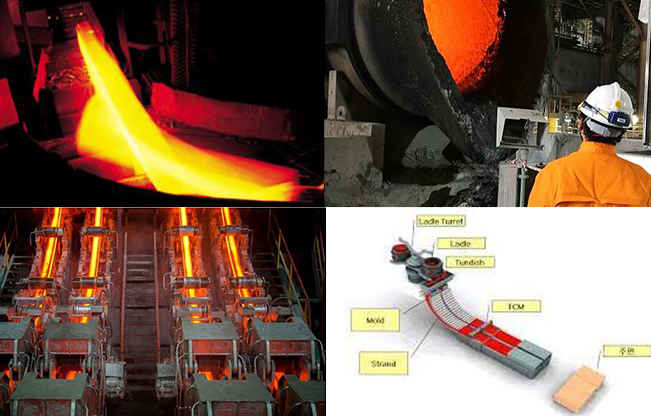

Steel is manufactured in the sequence of iron making, steel making, continuous casting, and rolling. Iron making is the process of melting iron ore. Steel making is the process of removing impurities from molten iron and make it as steel. Continuous casting is the process of turning molten iron into semi-finished product (intermediate material). Rolling is the process of manufacturing and processing semi-finished product in a variety of steel products.

Iron Making / Blast Furnace

Raw material, Sintering, Cokes, Blast furnace, etc.

After iron ore and coking coal are put in a blast furnace with about 100m in height, hot air of 1200℃ is blown in. The heat generated in the way of burning coking coal melts iron ore.

CO generated in the course of burning coking coal has reduction reaction with iron ore. In such a way, molten steel is manufactured.

In other words, coking coal not only serves as the heat source of melting iron ore, but separates oxygen and molten steel in oxidized steel.

It takes 5 to 6 hours to change the iron ore put in the blast furnace to molten steel. At t his time, the temperature of the molten iron goes up to 1500℃.

The molten iron contains not only steel components, but impurities like carbon or sulfur. It is called pig iron.

-

- POSCO Gwangyang Needle Cokes

-

- POSCO Gwangyang Ladle scall removal equipment

-

- POSCO Gwangyang Needle Cokes

-

- POSCO Gwangyang Ladle scall removal equipment

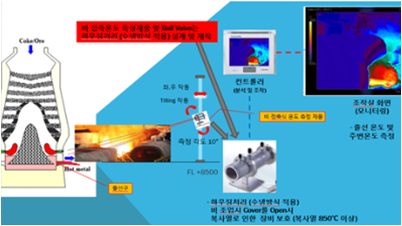

POSCO Gwangyang Blast Furnace No.1

Real time temperature measurement system

Reference

– POSCO Gwangyang Blast Furnace No. 1

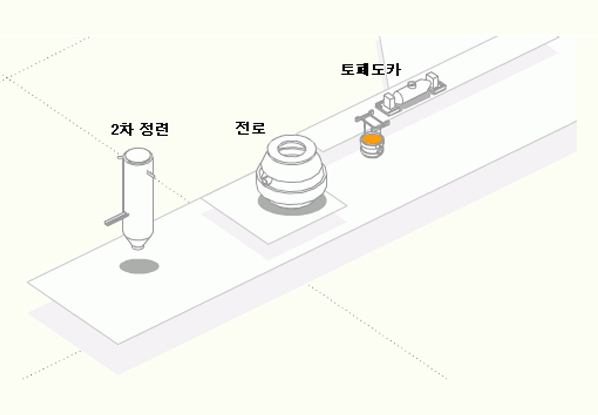

Steel Making / Continuous Casting

Steel Making

The molten iron produced in a blast furnace is rich in carbon (C) and contains impurities like phosphorus (P) and sulfur (S). It is called pig iron that is put in a converter. After scrap iron and pig iron are all put in the converter, pure oxygen is blown in. In this process, phosphorus, sulfur, and carbon are removed. The clean molten iron after the removal is called pig iron.

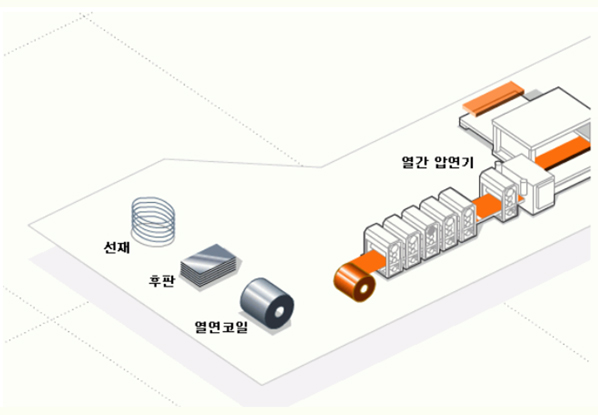

Continuous Casting

The liquid molten iron is injected in a mold, and gets cooled and coagulated in the course of passing a continuous caster. As a result, such intermediate materials, as slab, bloom, and billet are produced. In the process, bloom turns billet after passing a rolling machine, or is processed as a timber by a rolling machine for timber. Slab is produced as thick plate after passing a rolling machine for plate or is made as hot rolled steel plate after passing a hot rolling machine.

-

- Heat Protect Cover for POSCO Steel Making No. 2 Ladle Repair

-

- Ladle Cover

-

- Hot Rolling at POSCO Gwangyang Plate Factory Ring Removal System in Pig Iron Ladle

-

- Heat Protect Cover for POSCO Steel Making No. 2 Ladle Repair

-

- Ladle Cover

-

- Hot Rolling at POSCO Gwangyang Plate Factory Ring Removal System in Pig Iron Ladle

Reference

– POSCO Gwangyang Steel Making No. 1 & No. 2

Rolling / Cold Mill

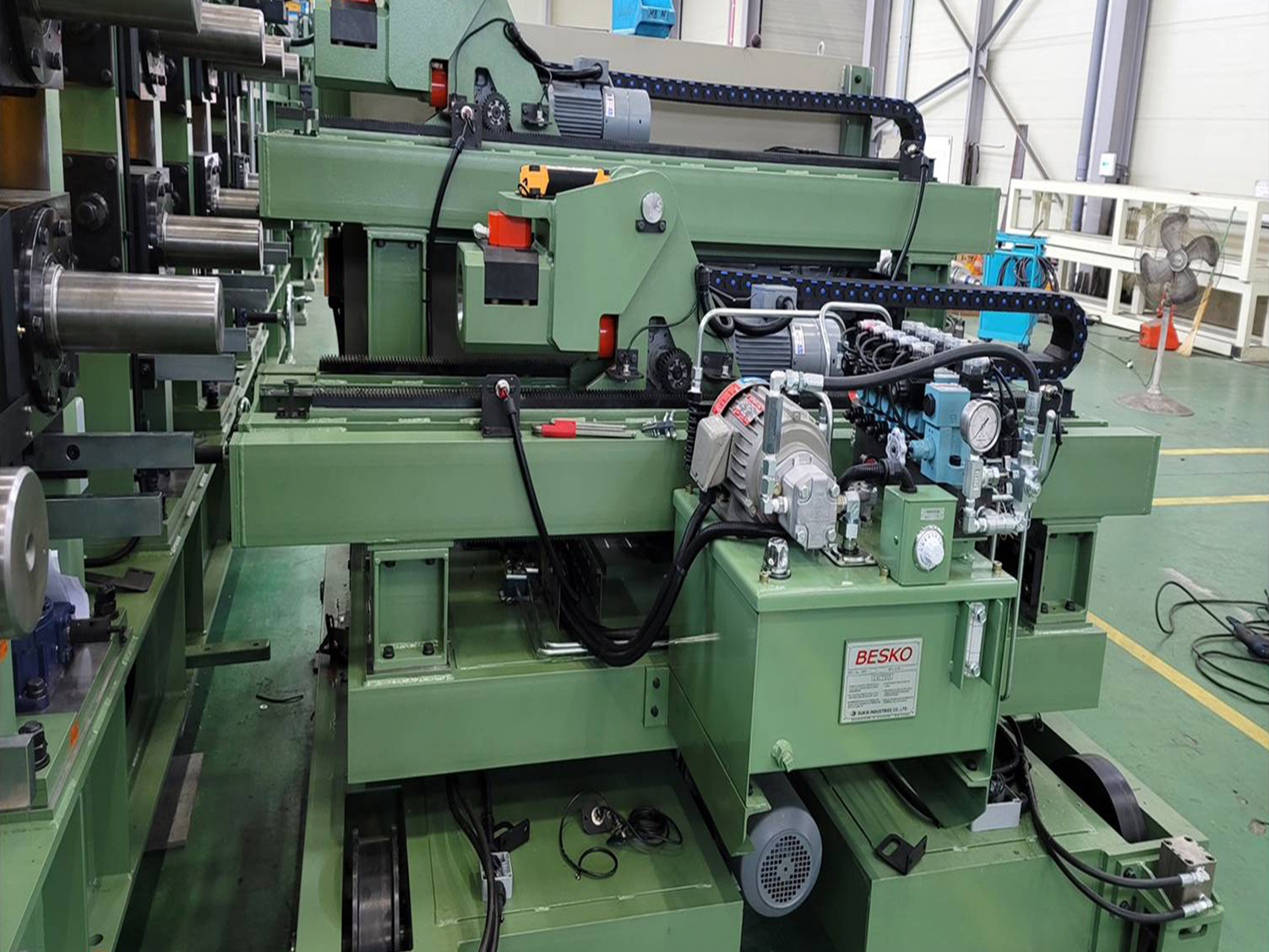

Hot Dip Galvanizing (COLD MILL) – Pre-Treatment

To galvanize (electro-galvanizing, hot dip galvanizing) the surface of steel plate, it is required to meet the conditions of the surface cleanness for good looking and adhesion. Alkaline degreasing agent (permeability, prevention of secondary pollution, emulsifiability, low-temperature degreasing, etc.) is applied to the steel surface through pressure-spray, brush roll based physical degreasing, or oxygen & hydrogen based ECT process using electrochemical properties, in order to purify the surface. For the process, it is possible to consist of the centrifugal separator to separate a degreasing agent from emulsified oil, the automatic washer of spray nozzle, oscillation of brush roll, the equipment for long life span of ECT electrodes, and ozone based degreasing device.

-

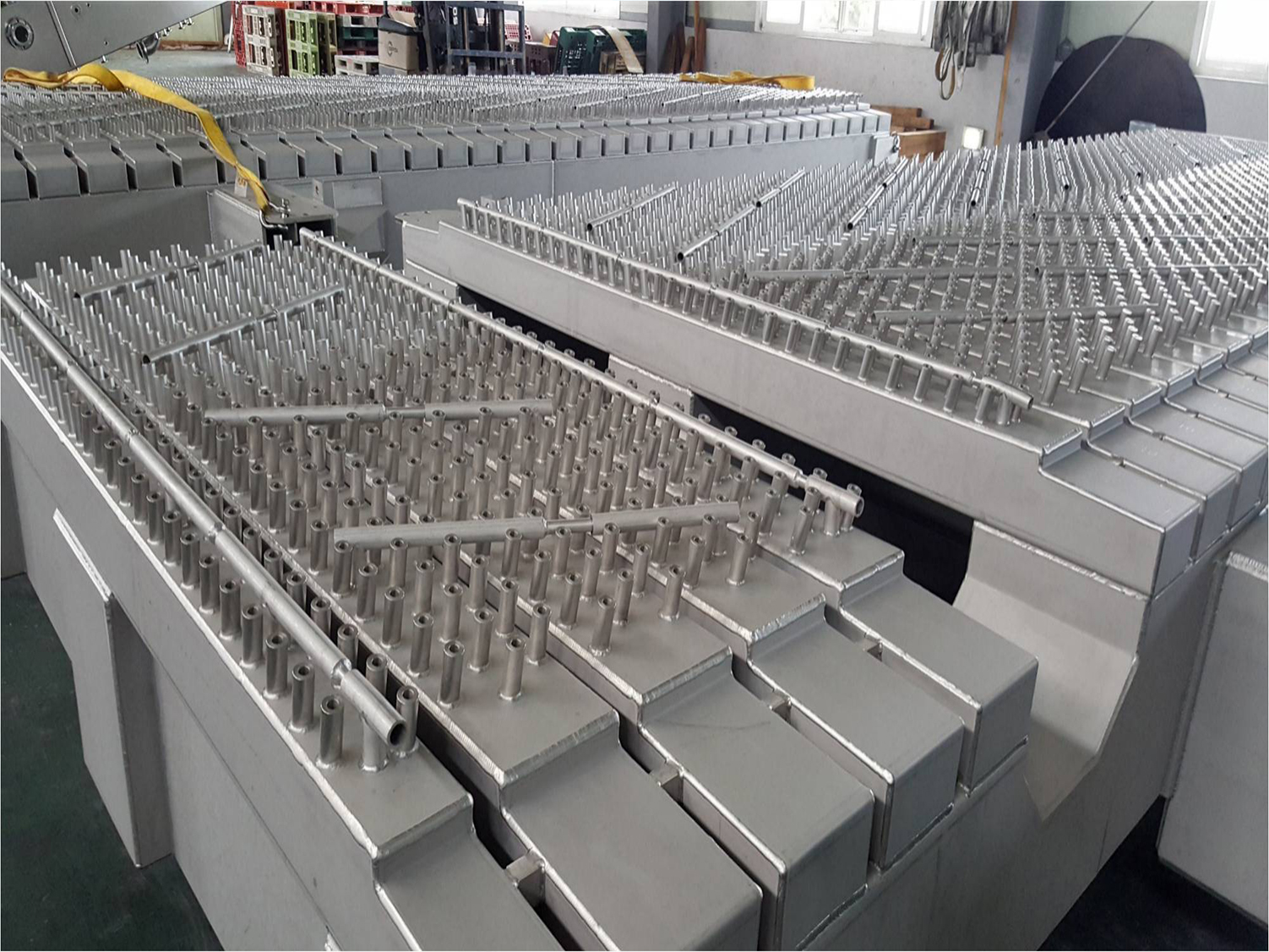

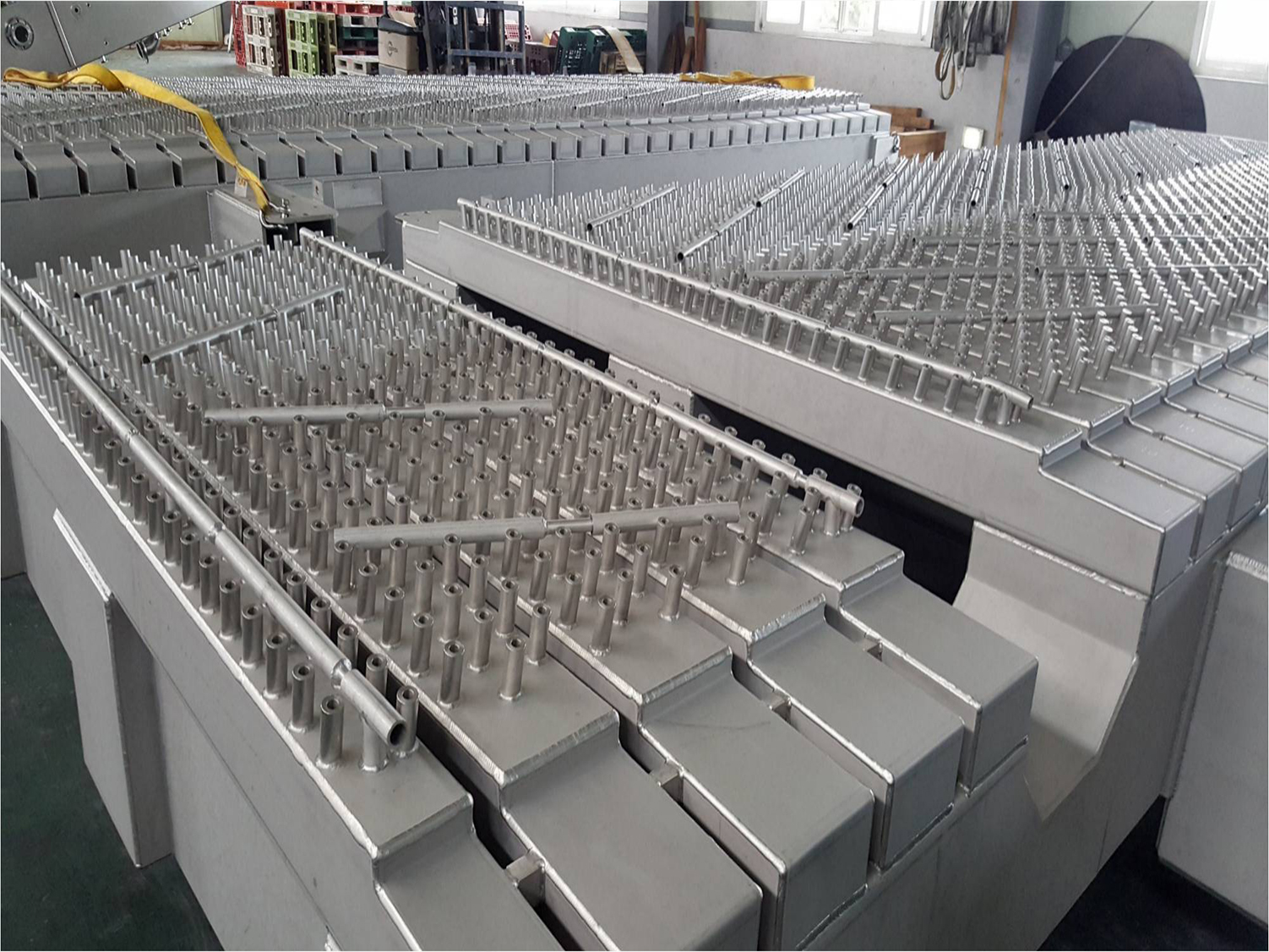

- Pre-Treatment Assembly

-

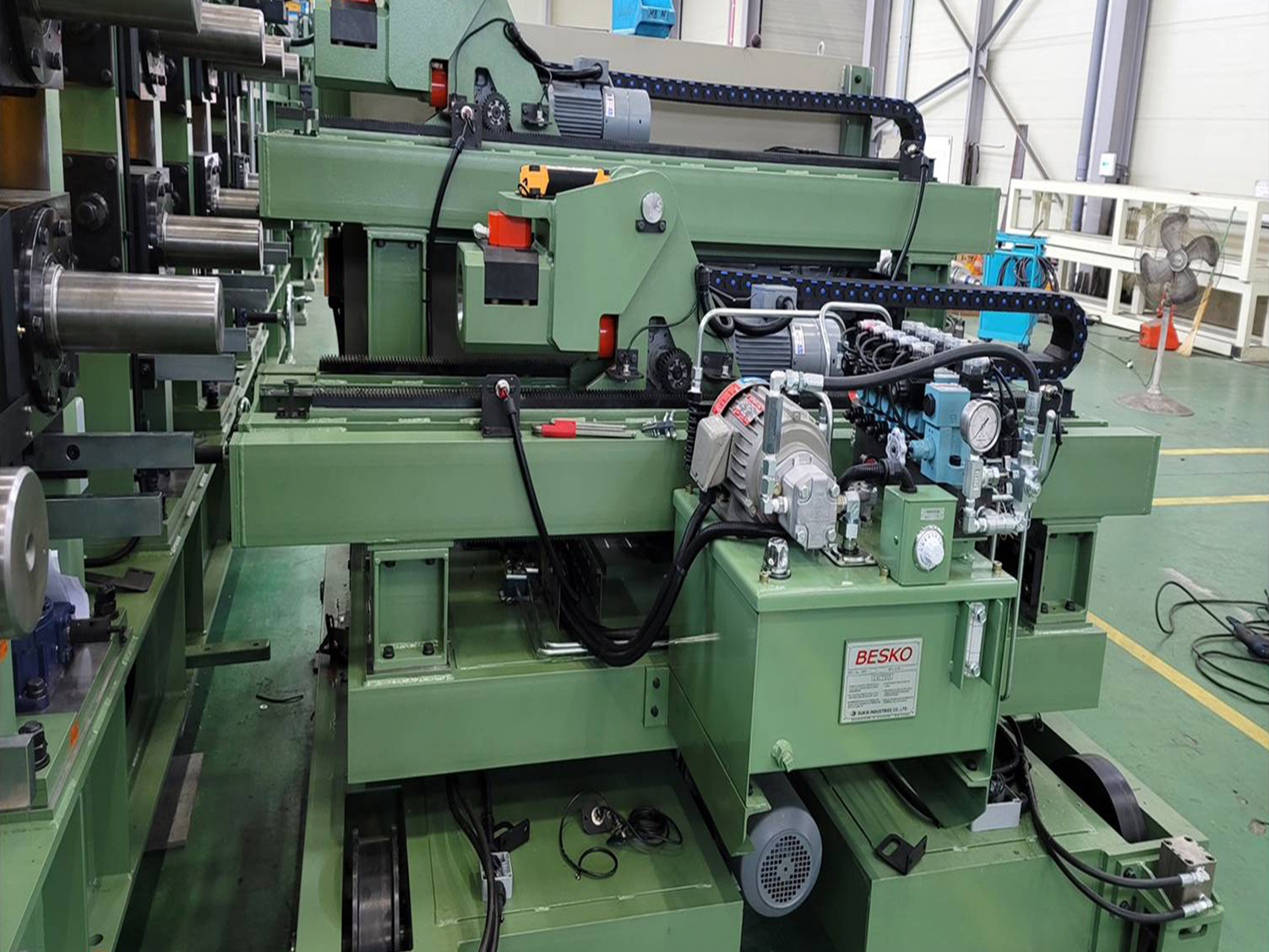

- Line Motor & Drive

-

- Roll Change Car & Jig

-

- Pre-Treatment Assembly

-

- Line Motor & Drive

-

- Roll Change Car & Jig

Reference

– POSCO GWANGYANG 5CGL, POSCO Maharashtra CGL, MSC CGL

Rolling / Cold Mill

Hot Dip Galvanizing (COLD MILL) – Coating Section

GI product (hot dip galvanizing used most for surface treatment is the equipment for injecting the F/H product, which passed pickling and rolling process, in CGL line, annealing continuously to secure a certain level of quality, passing a galvanizing tube at 460℃, and thereby coating the surface with zinc. Jet-Cooler & Pre-Cooler is used to control a melting point of zinc, suppress a size of spangle as most as possible, and make the product look beautiful. As for the strip that passed Air-Knife, its center and edge are cooled in the crown form through natural cooling or cooler’s cooling. Therefore, it is hard to secure the equal quality of product. To make the quality of strip equal, our company developed a special cooler that helps out uniform quality.

-

- Pre-Treatment Assembly

-

- Line Motor & Drive

-

- Roll Change Car & Jig

-

- Pre-Treatment Assembly

-

- Line Motor & Drive

-

- Roll Change Car & Jig

Reference

– POSCO 광양 1CGL, 3CGL, 5CGL, 7CGL, POSCO MEXICO CGL, CBASCO STEEL CGL

1-22, Geumchon-gil, Okgok-myeon, Gwangyang-si, Jeollanam-do

Call : +82 61 – 772 – 7781 ~ 5

Fax : +82 61 – 772 – 7746

© Copyright HANATECH CO., LTD. All rights reserved.

Design by 티제이웹 | admin

1-22, Geumchon-gil, Okgok-myeon, Gwangyang-si, Jeollanam-d

Call : +82 61 – 772 – 7781 ~ 5 Fax : +82 61 – 772 – 7746

© Copyright HANATECH CO., LTD. All rights reserved. Design by 티제이웹 | admin