Technology Development

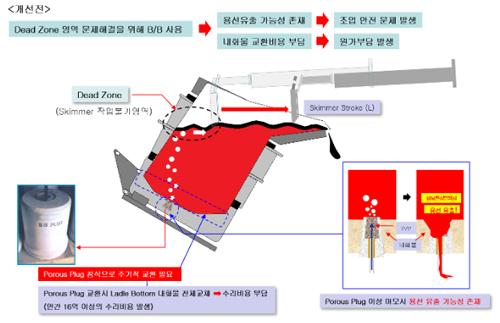

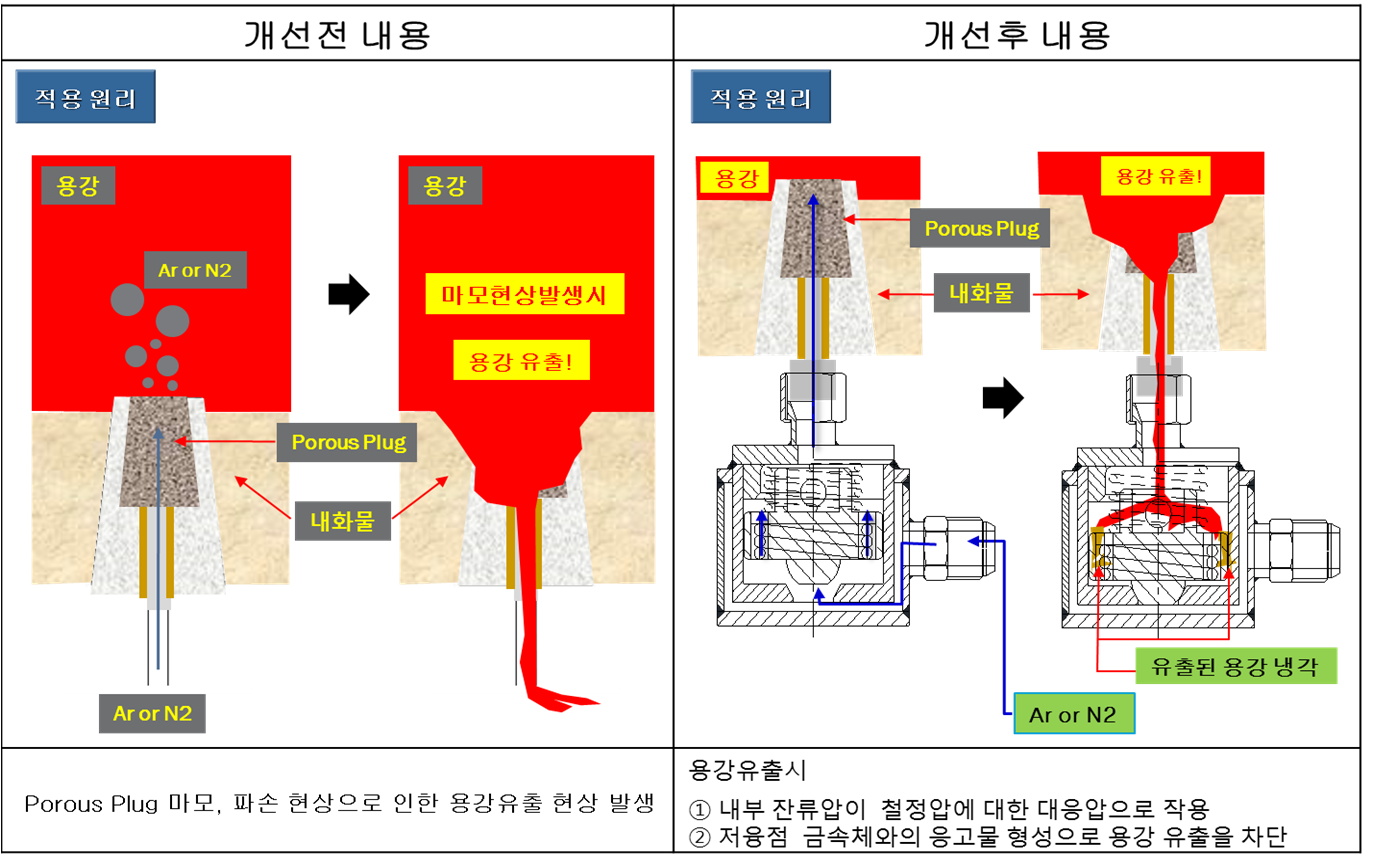

<Before improvement >

<After improvement>

Development of KR based Ladle Top Bubbling Device System

urrent State & Problems

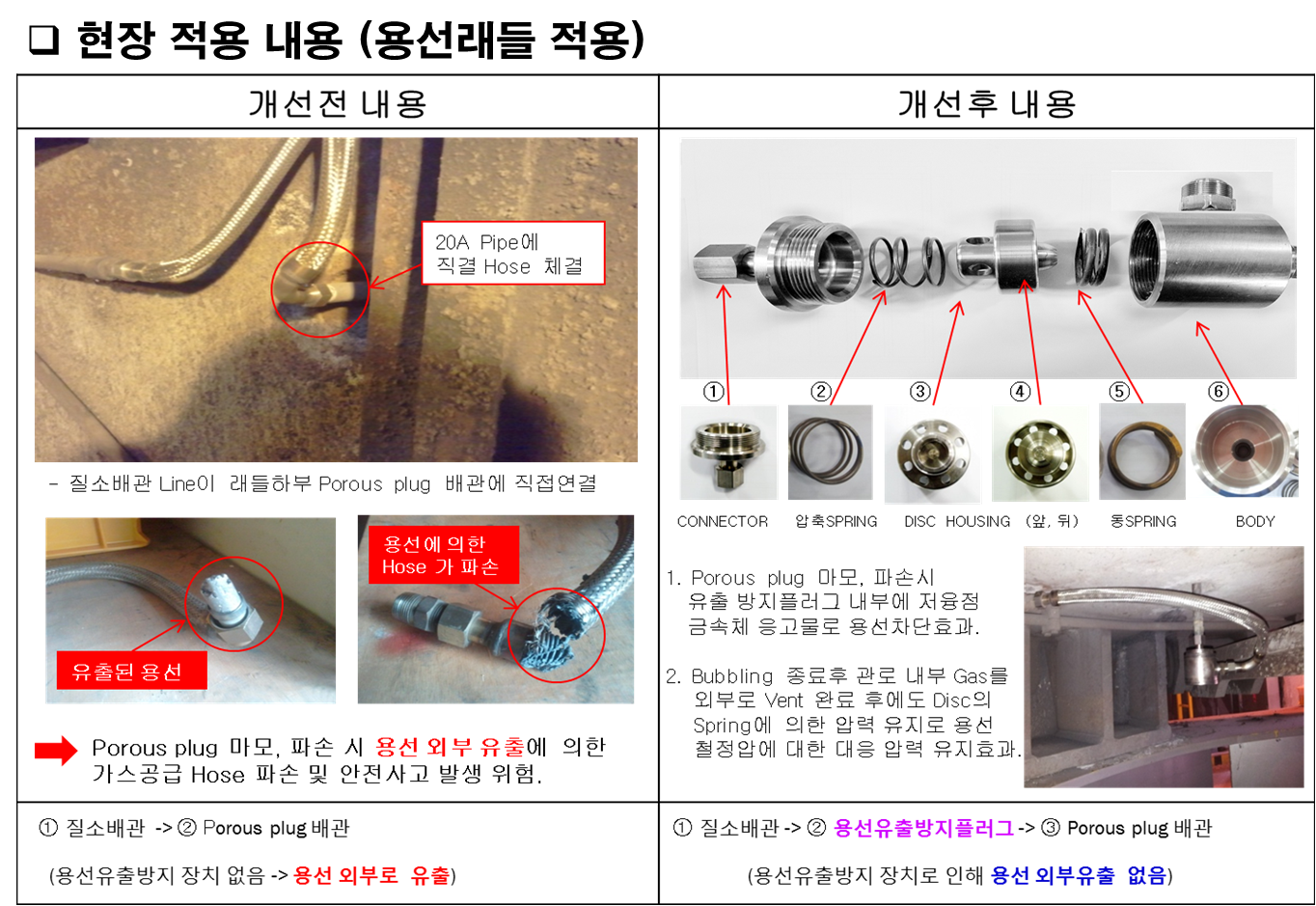

Both Skimmer Plate based Skimming Work and Bottom Bubbling are applied to remove slag as an impurity floating on the top of KR Ladle. In the process, Bottom Bubbling has the following problems:

1. There is the risk of pig iron leak accident if porous plug is abnormal or worn out.

2. It costs high to repair and repair the ladle. (The cost for replacing ladle brick due to worn-out porous plug)

Improvements

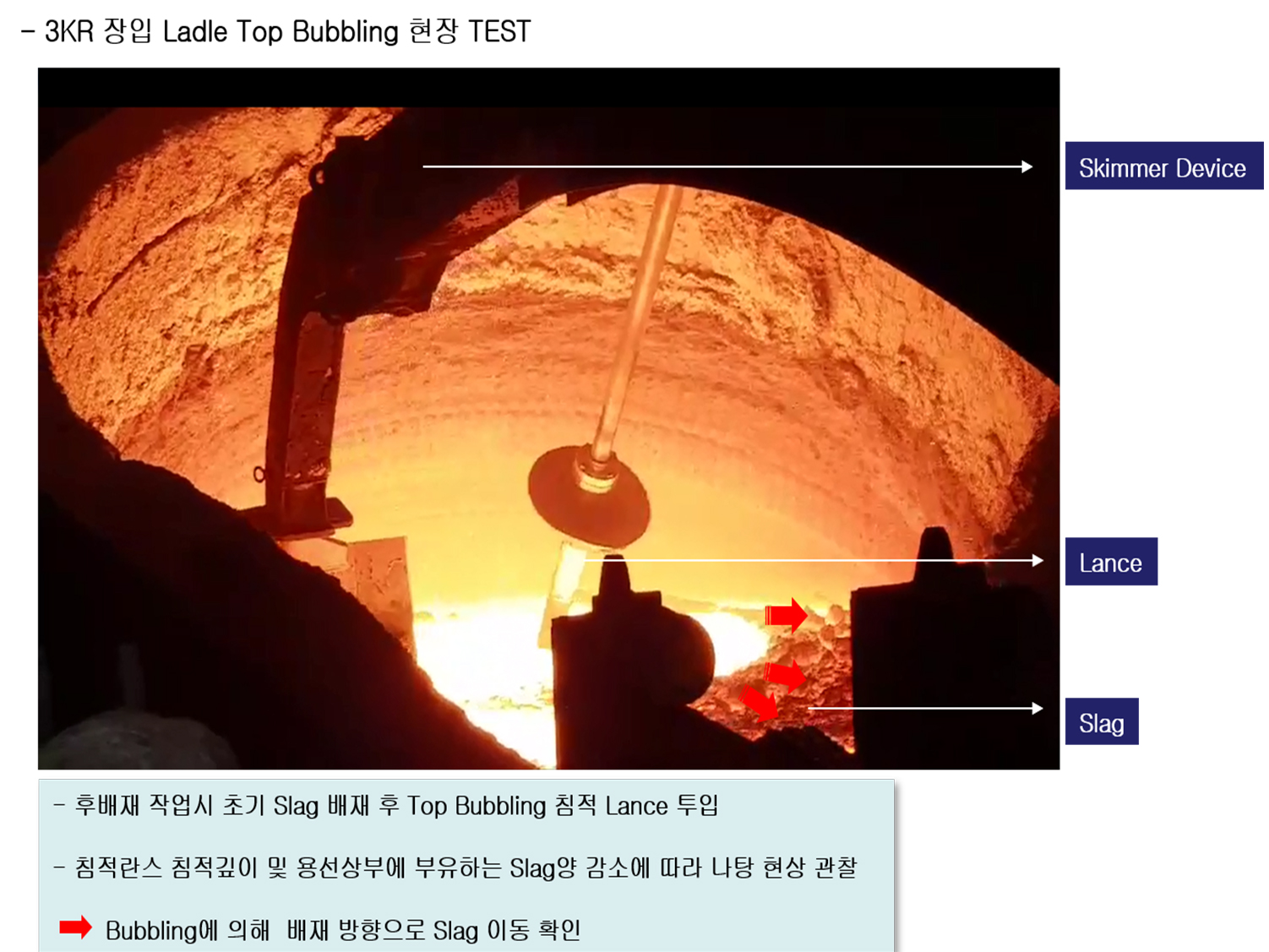

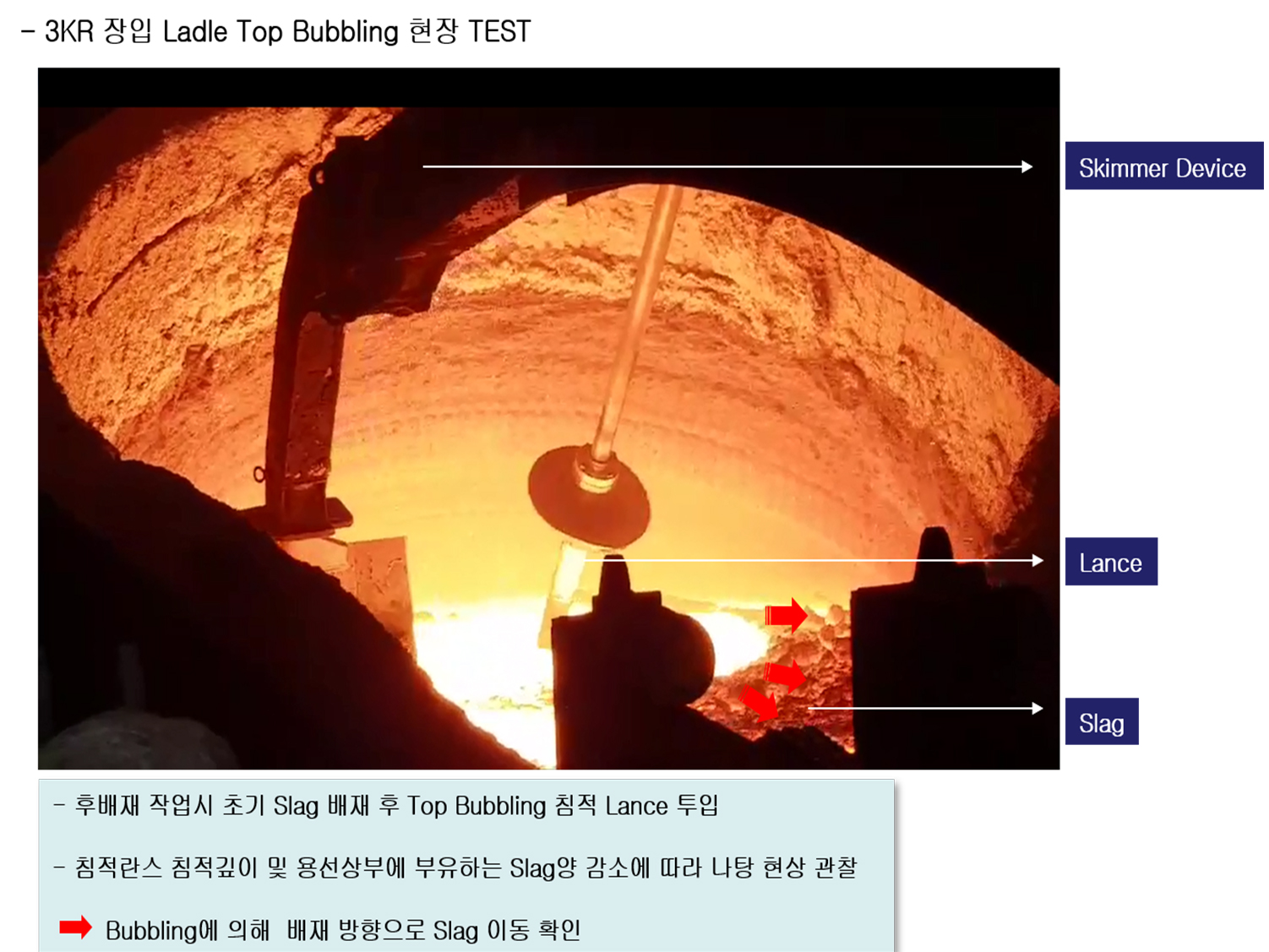

Changed from Porous Plug based Bottom Bubbling to Lance based Top Bubbling.

Free of the risk for pig iron leak

Shortened stroke distance of skimmer (shortened skimming time, and longer life span)

Improved bubbling effect by adjustable N2 pressure

-

- Picture of installation in a site

-

- Field Test (result of development)

-

- Ladle Top Bubbling Test

-

- Picture of installation in a site

-

- Field Test (result of development)

-

- Ladle Top Bubbling Test

Improvements in desulfurization efficiency and refining yield by applying SNNC Electric Furnace Ladle B/Bubbling System

Current State & Problems

Dead zone in the bottom of ladle leads to adhesion of lump metal. As a result, it is required to change refractory materials often. Such replacement also causes a rise in the price cost for production.( Since there is no Bottom bubbling function, LF treatment severely causes local erosion of Slag Line.)

Improvements

The system is used to inject Ar or N₂GAS in Ladle to adjust the temperature of the ladle or molten steel.

It is composed of Automatic Coupler for remodeling, attaching, and automatically coupling the ladle coupling part, and Valve Stand & Control Panel for utility supply and control.

Effects

Molten steel stirring effect to prevent the lump steel of slag on the bottom of ladle from being piled up Early development of the technology to manufacture unique and premium steel in an innovative process and the establishment of a stable manufacturing system. Bottom Bubbling operation for securing a worker’s safety, shortening a process time, and increasing an operating rate.

1-22, Geumchon-gil, Okgok-myeon, Gwangyang-si, Jeollanam-do

Call : +82 61 – 772 – 7781 ~ 5

Fax : +82 61 – 772 – 7746

© Copyright HANATECH CO., LTD. All rights reserved.

Design by 티제이웹 | admin

1-22, Geumchon-gil, Okgok-myeon, Gwangyang-si, Jeollanam-d

Call : +82 61 – 772 – 7781 ~ 5 Fax : +82 61 – 772 – 7746

© Copyright HANATECH CO., LTD. All rights reserved. Design by 티제이웹 | admin