Technology Development

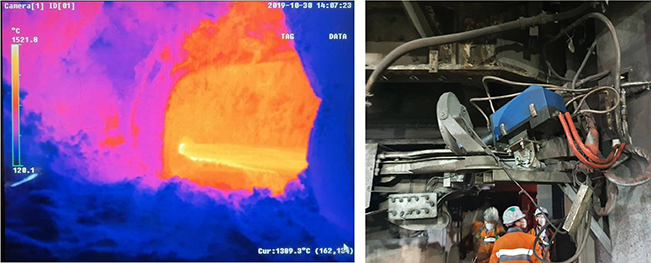

Installation of a thermal imaging camera

– Image of camera measurement

Development of the technology of the system to measure pig iron of tap hole in blast furnace (BIMS)

A blast furnace is used to put iron ore in a furnace to make melted iron for casting. In the operation of a blast furnace, the temperature of pig iron is a critical factor to determine quality of steel. The purposes of the development of this system are to measure the temperature of the tap hole of the blast furnace in a non-contact way in real time in order to monitor surroundings, to display the measured real-time temperature data after being program ed, to find the temperature of pig iron by extracting and programming the data in a particular area with an optimal algorithm, to estimate the temperature condition of pig iron in the blast furnace, and thereby to improve a rate of operation and save cost price.

The system supports non-contact measurement according to a change in the tap hole of blast furnace, checking frequently the temperature of the pig iron in the furnace installed 6M away from the tap hole. Expectancy effects: improved operation efficiency [Si] and cost saving [consumable-type T/C] by shortening the measurement time of the temperature of pig iron

The real-time measurement of temperature makes it possible to find the temperature of the pig iron emitted by the tap hole on line. Therefore, at the beginning, it is possible to check the temperature of pig iron without investing as much fuel cost [COKE] as the calorie equivalent to a runner’s loss.

-

- Picture of a site

-

- Picture of installation in a site

-

- Picture of installation

-

- Picture of a site

-

- Picture of installation in a site

-

- Picture of installation

1-22, Geumchon-gil, Okgok-myeon, Gwangyang-si, Jeollanam-do

Call : +82 61 – 772 – 7781 ~ 5

Fax : +82 61 – 772 – 7746

© Copyright HANATECH CO., LTD. All rights reserved.

Design by 티제이웹 | admin

1-22, Geumchon-gil, Okgok-myeon, Gwangyang-si, Jeollanam-d

Call : +82 61 – 772 – 7781 ~ 5 Fax : +82 61 – 772 – 7746

© Copyright HANATECH CO., LTD. All rights reserved. Design by 티제이웹 | admin