Technology Development

Before improvement (import)

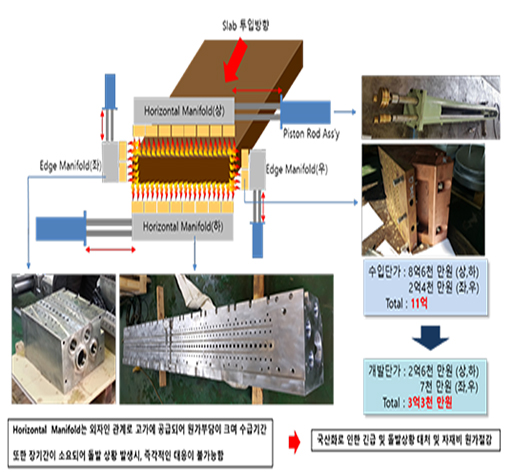

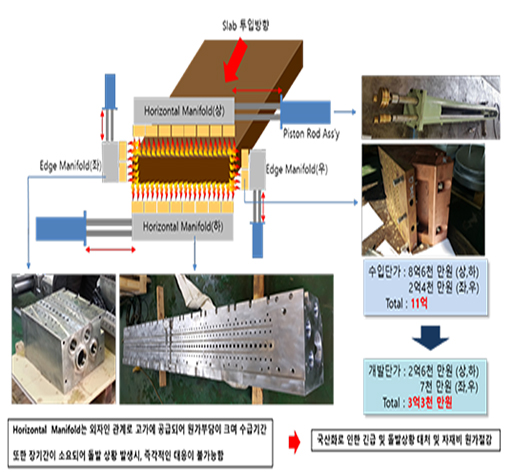

Localization of Manifold Block of 4-side Scrarfer of Slab Correction Line of POSCO Gwangyang Continuous Casting Factory.

Supplying Horizontal Manifold costs high and takes long, since it a foreign resource needs to be imported. It is impossible to respond immediately to an unexpected accident. Piston Rod Assembly used currently prevents the gas leak in the Manifold and in a transfer section. Friction with Piston Head causes Gaskets to worn out, leading to gas leak. In addition, frequent damage to the Head makes it difficult to maintain the equipment. There is the high risk of gas explosion at work. For these reasons, it is necessary to make structural improvements and save cost price through localization.

After improvement (localization)

Localization of imported product / Piston Head improvement in consideration of efficiency and stability

Piston Head welding part Upgrade to the movable head structure to prevent piston head separation caused by deformation and abrasion

Piston Head part Add Slot Oxygen Line to Piston head on the top in order to improve scarfing quality (the bottom excluded)

Body part Improvements in thickness for the prevention of thermal deformation and the application of Schedule Pipe

Guide Roller Improvements in the roller shape and rail part for preventing the (forward/backward) guide roller from being separated in use / Addition of grease nozzle

Guide Roller Bracket Improvement in the guide roller bracket to prevent cracks and deformation (welding type -> integration type)

-

- BS Project: improvements

-

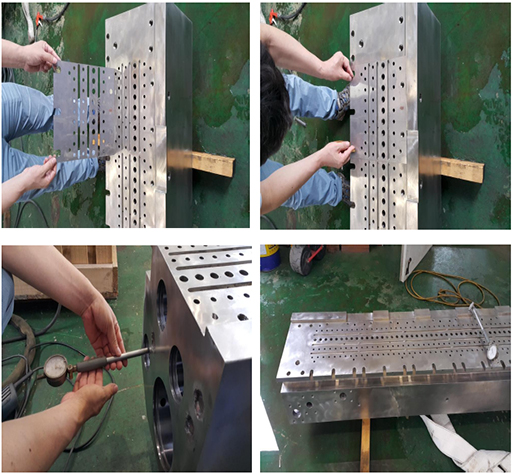

- Manifold Assembly & JIG Inspection

-

- Manifold TEST

-

- BS Project: improvements

-

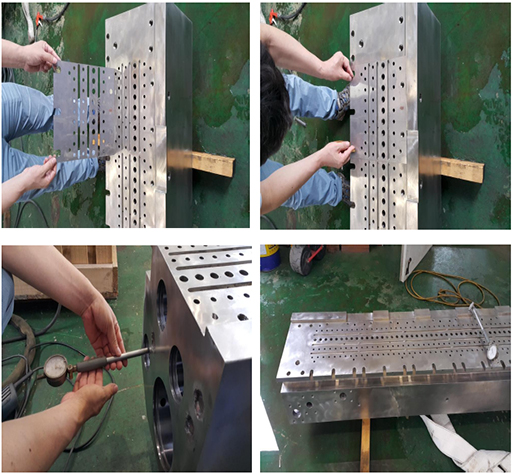

- Manifold Assembly & JIG Inspection

-

- Manifold TEST

1-22, Geumchon-gil, Okgok-myeon, Gwangyang-si, Jeollanam-do

Call : +82 61 – 772 – 7781 ~ 5

Fax : +82 61 – 772 – 7746

© Copyright HANATECH CO., LTD. All rights reserved.

Design by 티제이웹 | admin

1-22, Geumchon-gil, Okgok-myeon, Gwangyang-si, Jeollanam-d

Call : +82 61 – 772 – 7781 ~ 5 Fax : +82 61 – 772 – 7746

© Copyright HANATECH CO., LTD. All rights reserved. Design by 티제이웹 | admin