Technology Development

-

- Completely packed coil

-

- Steel Band removal by cutter

-

- Completely packed coil

-

- Steel Band removal by cutter

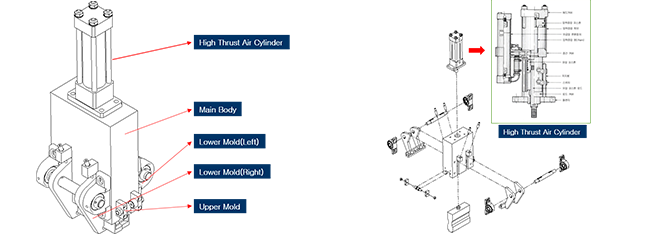

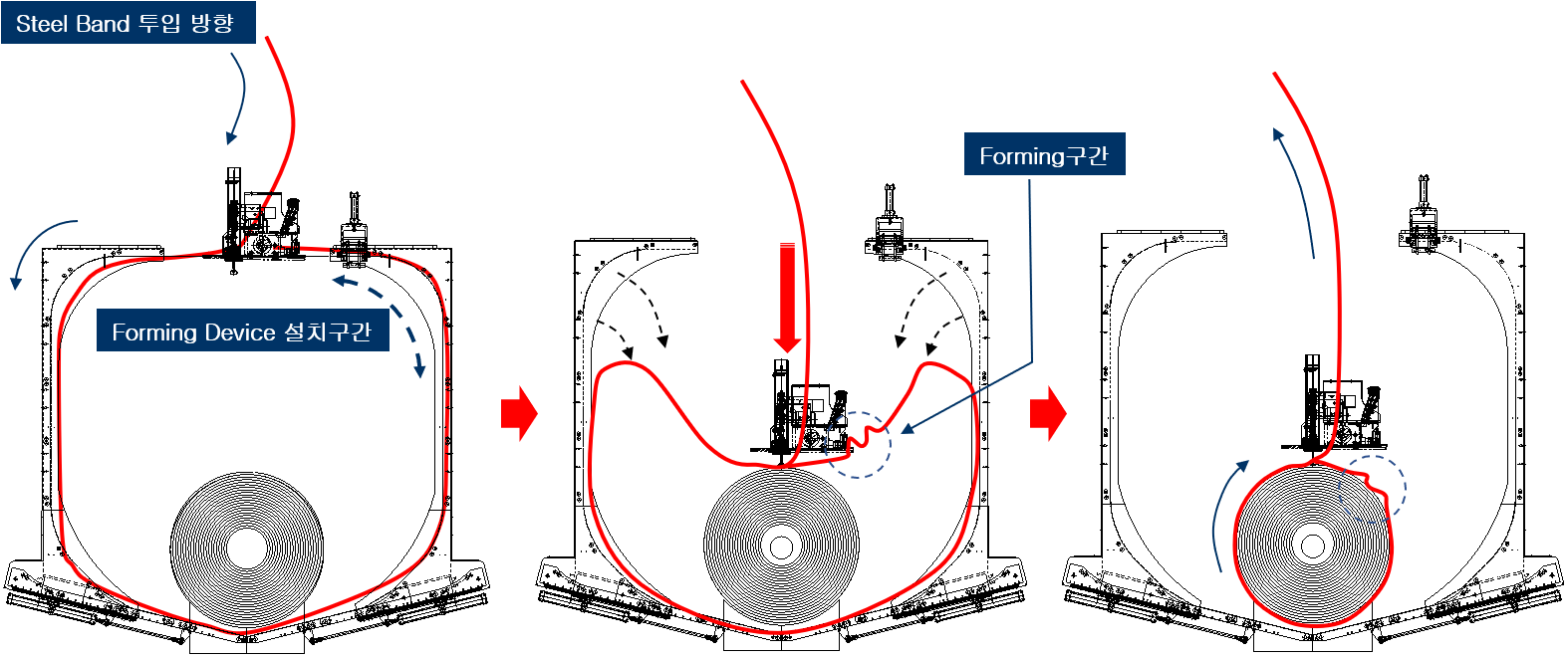

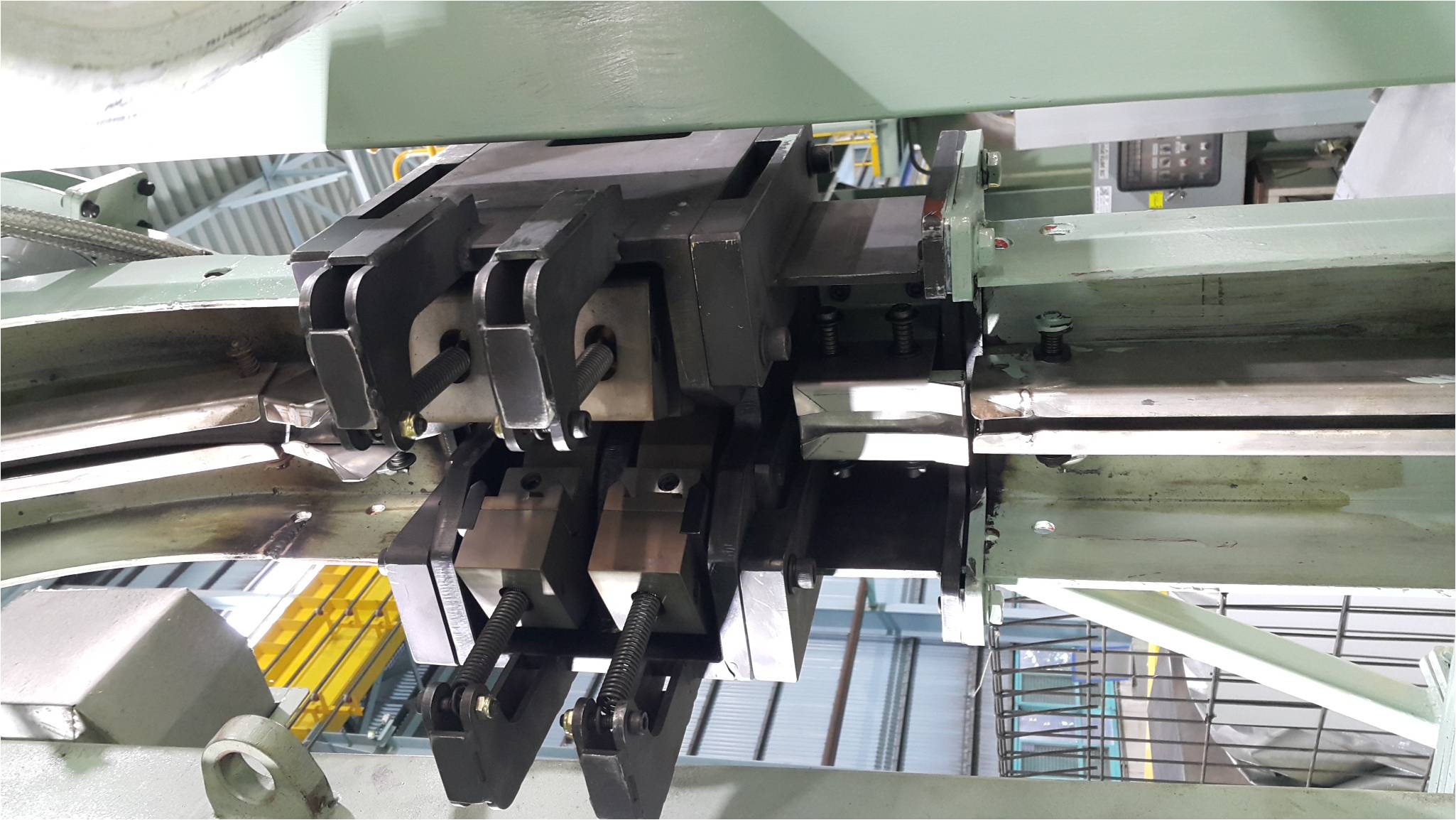

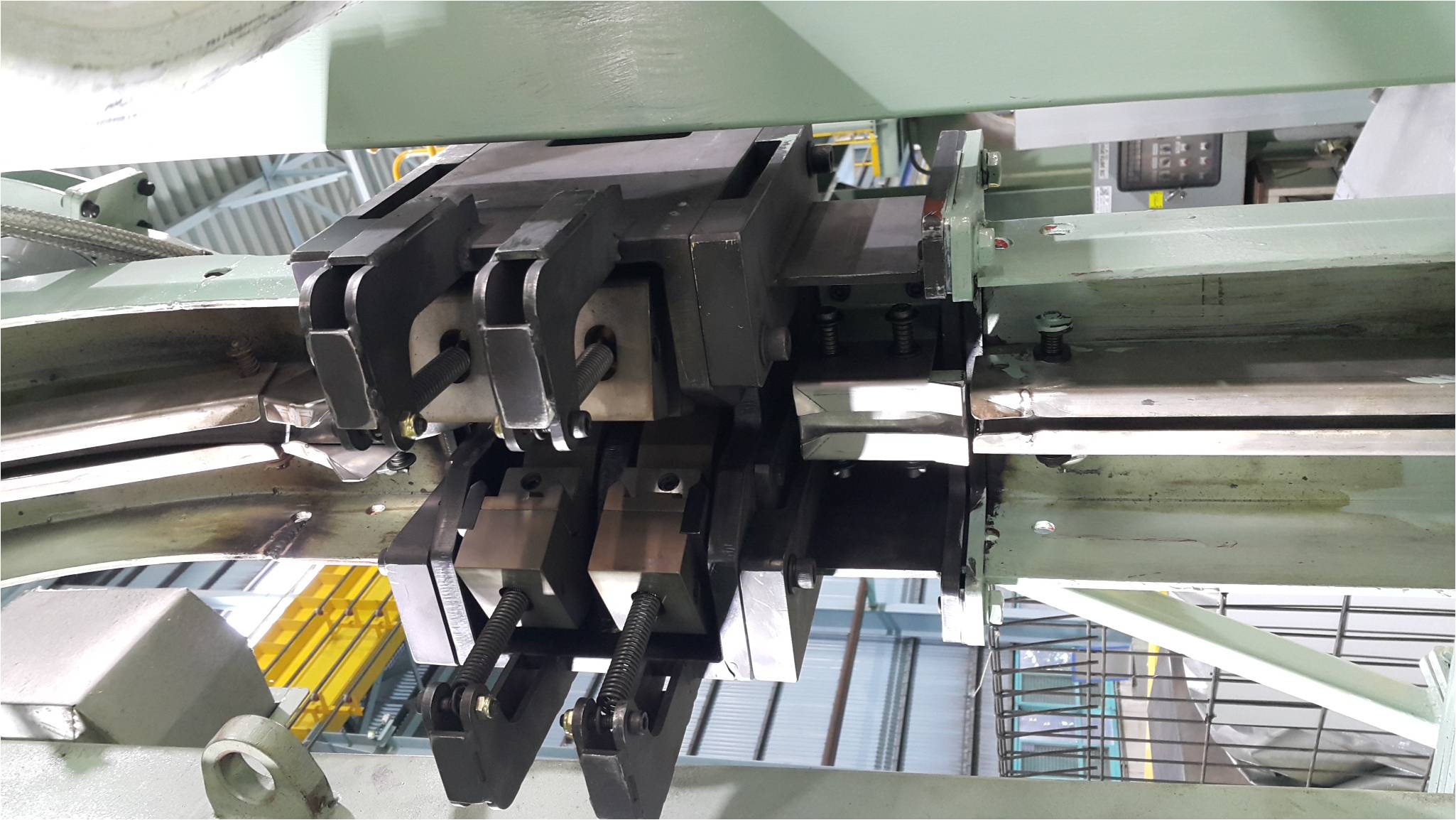

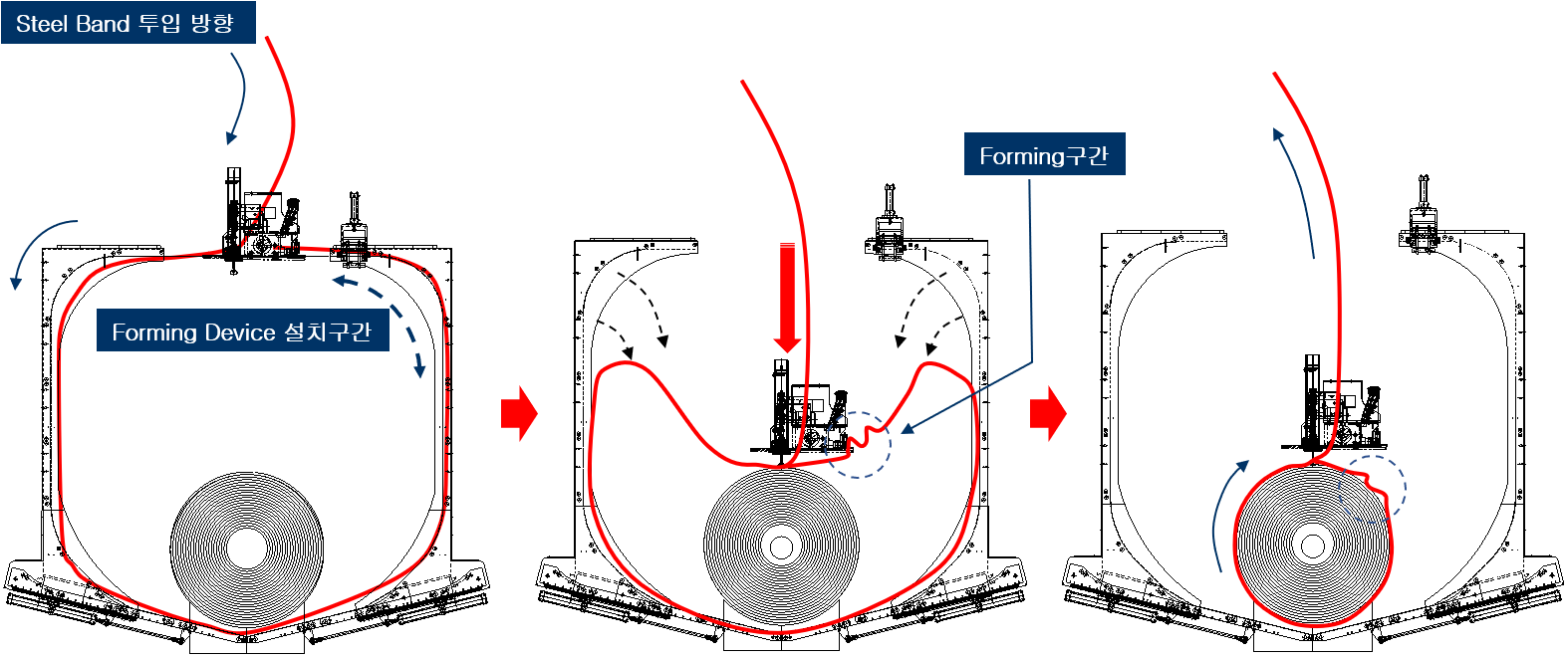

Development of Steel Band Forming Device & System

Development of Steel Band Forming System for Coil

Current State & Problems

The coil wound up completely is automatically welded to the overlay part of Steel Band in order for the connection and binding of the steel band inserted by Auto Bending Machine. After that, the steel band is cut and packed.

The coil packed completely is transported to a purchaser after being sold. For the use of the coil, the welded steel band is removed. In this case, the cutting device or cutter for steel band is forced to be put in between the steel band bond with the coil, and the is cut.

In such a process, the blade of the cutter causes scratches or damage not only to the package but on the surface of the coil, which generate any defect of the coil. As a result, a large amount of coil fails to be used and is wasted.

Given customer inconvenience and voice of customer (VOC), it is urgent to make improvements. (No space for cutting)

System development effects

1.Cutting without any damage to the coil surface

2. Quality improvement and cost saving by reduction in coil defects

3. Shortened cutting time and improved work efficiency (handling VOC)

4. Prevention of safety accident by an unskillful worker’s removal of steel band

-

- Steel Band Forming Device

-

- Installation of Steel Band Forming Device

-

- Steel Band Forming Device

-

- Installation of Steel Band Forming Device

Pilot Electro-Plating Line 1LOT

pH value of Ni-Flash solution is 1.2-2.4 approximately (strong acid). Reduction in scattered pattern through the improvement in solution pH

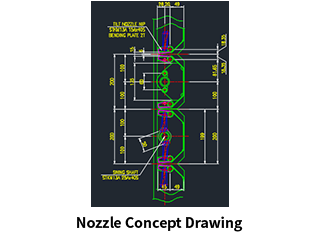

The structural improvement in the nozzle of electrolytes makes it possible to supply electrolytes evenly without any mixture of the bubble layer in the plating tank, and to generate the uniform plating layer on the surface through the inhibition of the flow of electrolytes.

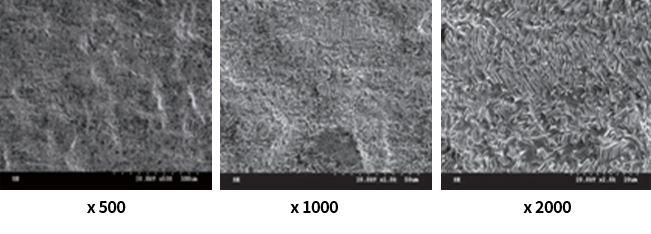

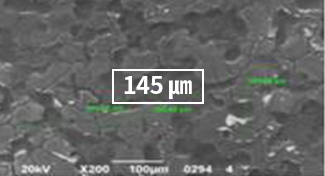

Plating tissue after Nozzle remodeling (no spotted pattern and compact plating tissue )

-

- Electro-Plating Unit

-

- Entry Section

-

- Alkali Cleaning Unit

-

- Electro-Plating Unit

-

- Entry Section

-

- Alkali Cleaning Unit

Steel Band Forming Device 및 System 개발

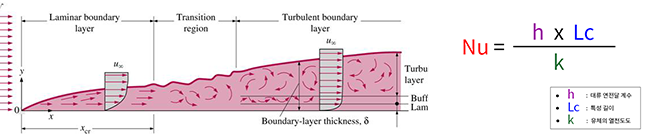

Continuous Galvanizing Line-Coating Section-Air Jet Cooler

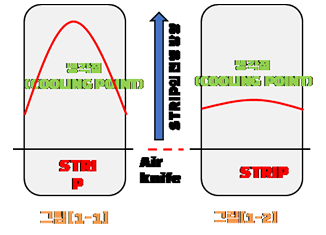

With the naked eye, the cooling is processed in the form of crown, as shown in Fig. [1-1]. That is important for quality of steel plate. That is because it is hard to make the quality at the center and corner even in the crown-shaped cooling state, and because there is a large difference in the size of spangle.

JET-COOLER is used to lower the surface temperature of steel plate. Nevertheless, the first objective of the system is to change the crown-shaped cooling state to the one shown.

The cooling form by fluid flow [Analysis of complex cooling mechanism]

– Nusselt’s Number

It is the ratio of convective to conductive heat transfer at a boundary in a fluid. In this case, conductivity and convection current pass the same fluid layer.

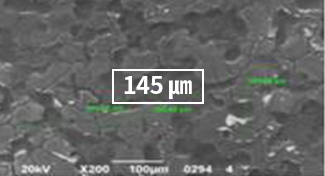

Quality of steel plate: Spangle Size verified

-

- 0.8T / K120 / 110mpm

-

- 0.9T / K120 / 120mpm

-

- 0.8T / K120 / 110mpm

-

- 0.9T / K120 / 120mpm

1-22, Geumchon-gil, Okgok-myeon, Gwangyang-si, Jeollanam-do

Call : +82 61 – 772 – 7781 ~ 5

Fax : +82 61 – 772 – 7746

© Copyright HANATECH CO., LTD. All rights reserved.

Design by 티제이웹 | admin

1-22, Geumchon-gil, Okgok-myeon, Gwangyang-si, Jeollanam-d

Call : +82 61 – 772 – 7781 ~ 5 Fax : +82 61 – 772 – 7746

© Copyright HANATECH CO., LTD. All rights reserved. Design by 티제이웹 | admin