-

- POSCO Gwangyang Needle Cokes

-

- POSCO Gwangyang Ladle scall removal equipment

-

- POSCO Gwangyang Needle Cokes

-

- POSCO Gwangyang Ladle scall removal equipment

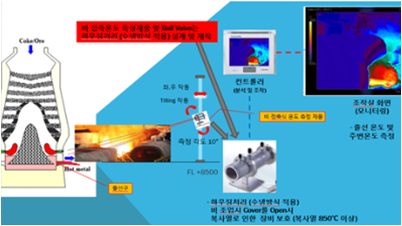

POSCO Gwangyang Blast Furnace No.1

Real time temperature measurement system

Reference

– POSCO Gwangyang Blast Furnace No. 1